Saothrachadh cuir-ris Pùdar stàilinn stainless 316l pùdar airson clò-bhualadh 3d

Tuairisgeul toraidh

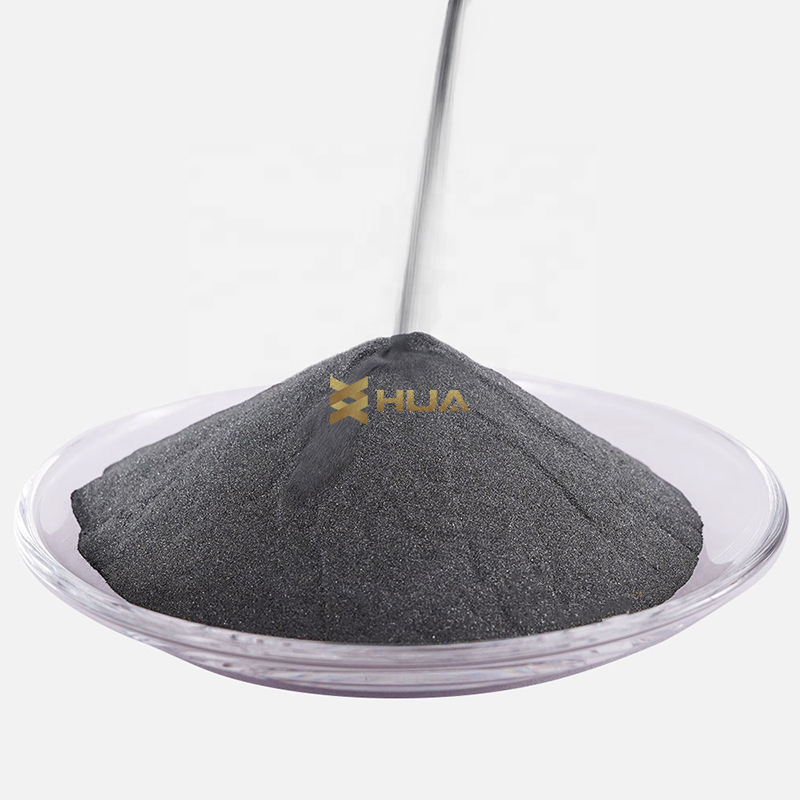

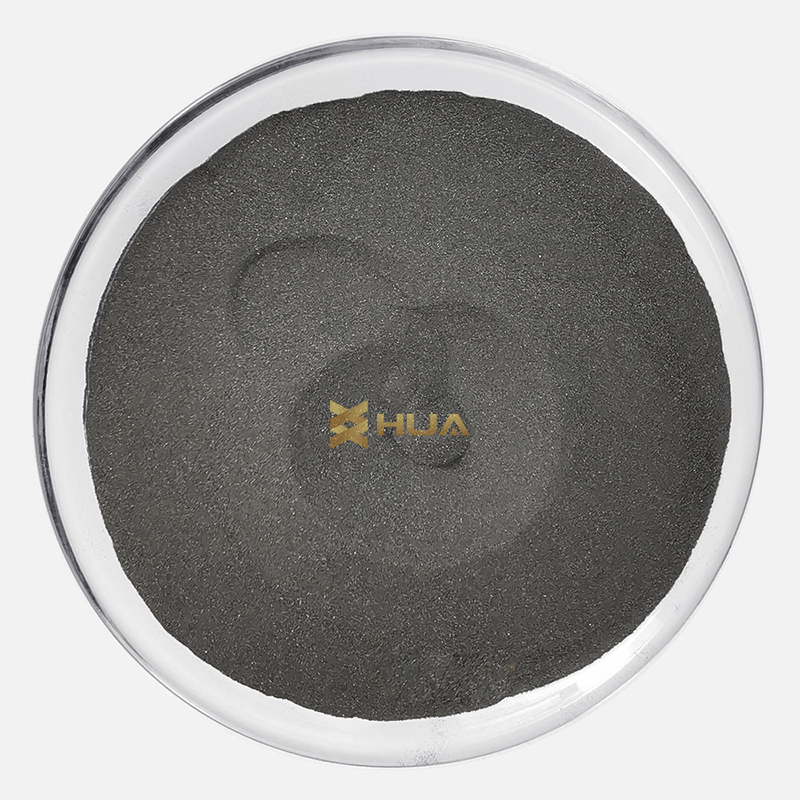

Tha pùdar stàilinn gun staoin air a dhèanamh le pròiseas atomization uisge agus tha deagh sheasamh an aghaidh creimeadh agus seasmhachd.Tha raon farsaing de chleachdaidhean gnìomhachais aig pùdar stàilinn.

Thoir seachad measgachadh de phùdar meatailt stàilinn gun staoin le diofar mheudan gràin.

A rèir cleachdadh

1.Hot Isostatic Press

2.Metal Injection Moulding

Clò-bhualadh 3.3D

4.Thermal spraeadh

A rèir pròiseas toraidh

1.Water atomization

2.Water gas còmhla atomization

3.Gas atomization

4.Vacuum atomization

Mion-fhiosrachadh sònrachaidh

| Co-dhèanamh pùdar stàilinn stainness % | |||||||||

| Ìre | Cr | Ni | Mo | Nb | Cu | S | P | C | Si |

| 303 | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.15 | ≤1 |

| 304 | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 316 | 16-18 | 10-14 | 2-3 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303L | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304L | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316L | 16-18 | 10-14 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 317L | 18-21 | 12-16 | 3-4 |

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 314 | 24-27 | 18-21 |

|

|

| ≤0.03 | ≤0.04 | ≤0.2 | 1.5/2.5 |

| 310 | 24-26 | 19-22 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303LSC | 17-19 | 8-13 |

|

| 2 | 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304 LSC | 17-19 | 8-13 |

|

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316LSC | 16-19 | 10-14 | 2-3 |

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410L | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 430L | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 434L | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434LNB | 16-18 |

| 0.75-1.25 | 0.4-0.6 |

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410 | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.25 | ≤1 |

| 420 | 12-14 |

|

|

|

| ≤0.03 | ≤0.04 | 0.25/0.35 | ≤1 |

| 430 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434 | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 440 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | 0.9/1.2 | ≤1 |

| 17-4PH | 15-17,5 | 3-5 |

| 0.15-0.456 | 3-5 | ≤0.03 | ≤0.04 | ≤0.07 | ≤1 |

| 15-5PH | 14-15,5 | 3.5-5.5 |

|

| 2.5-4.5 | ≤0.03 | ≤0.04 | <=0.07 | ≤1 |

Iarrtas

Faodar pùdar stàilinn gun staoin a chleachdadh airson frasadh teirmeach, meatailteachd pùdarrach, sintering preas meatailte pùdar (PM), sìoltachan sintering cumadh in-stealladh (MIM), msaa, susbaint ocsaidean atomization uisge<4000PPM, gas atomization<1000PPM.

Buannachd de phùdar stàilinn stainless HUARUI

● Eadhon co-dhèanamh pùdar, nas lugha de neo-chunbhalachd

● Sphericity àrd

● Ìosal susbaint ocsaidean

● Math flowability

● Dùmhlachd sgaoilte àrd, dùmhlachd tap àrd

● Nas lugha de phùdar falamh, nas lugha de phùdar saideal

Siostam smachd càileachd

Tha siostam riaghlaidh càileachd teann aig 1.Huarui.Bidh sinn a’ dèanamh deuchainn air na toraidhean againn an-toiseach às deidh dhuinn crìoch a chuir air an riochdachadh againn, agus bidh sinn a’ dèanamh deuchainn a-rithist ro gach lìbhrigeadh, eadhon sampall.Agus ma tha feum agad air, bu mhath leinn gabhail ri treas phàrtaidh airson deuchainn.Gu dearbh ma thogras tu, b’ urrainn dhuinn sampall a thoirt dhut airson deuchainn.

2.Our càileachd toraidh air a ghealltainn le Sichuan Metallurgical Institute agus Guangzhou Institute of Metal Research.Faodaidh an co-obrachadh fad-ùine leotha tòrr ùine deuchainn a shàbhaladh dha luchd-ceannach.